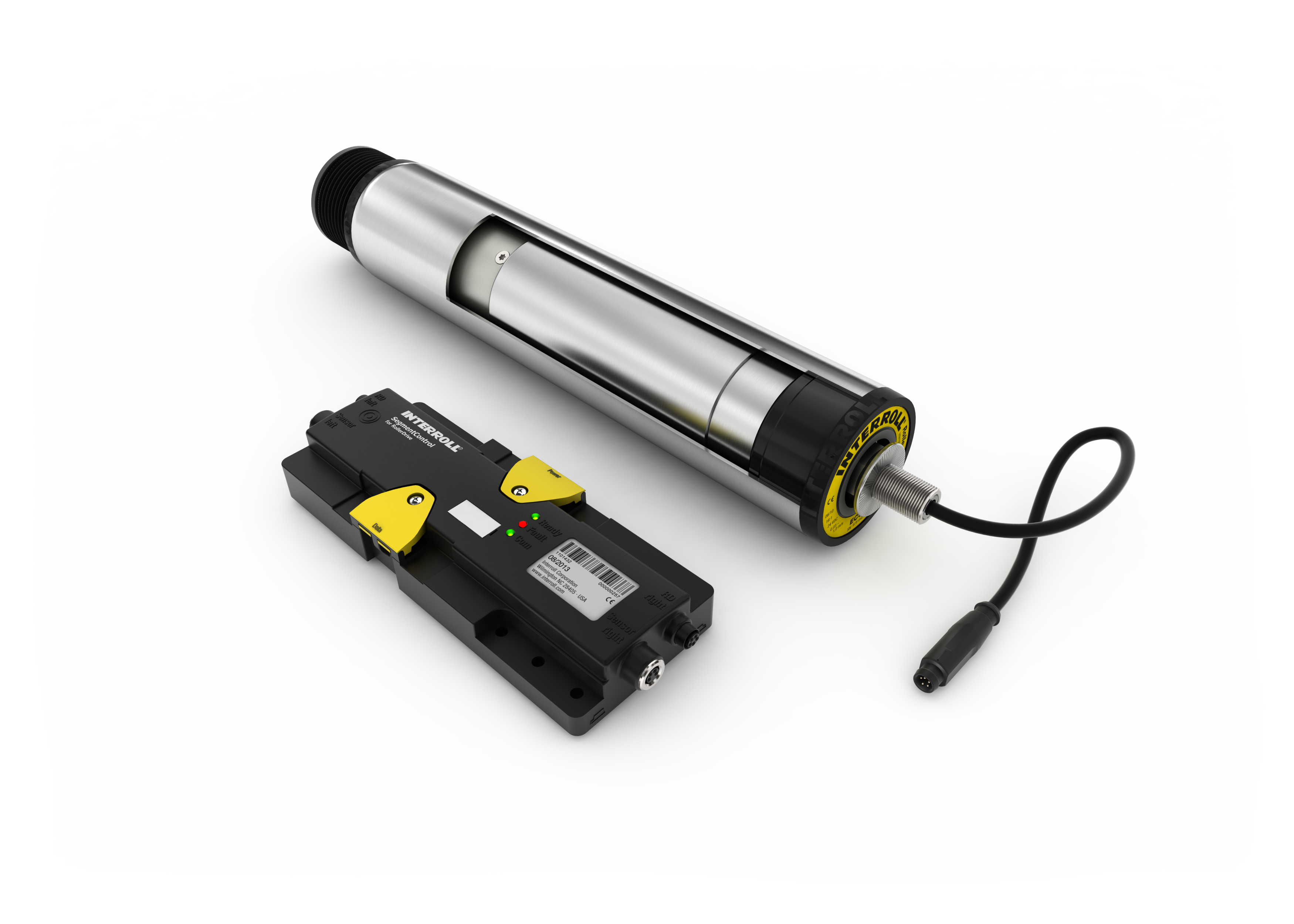

Interroll RollerDrive

Description

Interroll RollerDrive – RollerDrive and Controls are based on a simple principle: one motor for all applications. Interroll RollerDrive and Controls are used in automated conveyor technology. They are based on decentralised drive technology and can thus directly ensure that systems can be adapted to individual requirements.

The Interroll RollerDrive is a 24 VDC brushless motor integrated in a conveyor roller, which can be employed in the most diverse conveyor systems. Many years of experience and many hundreds of thousands of 24V motor rollers in use make Interroll the leading manufacturer in this area. A broad spectrum of controllers allows for flexible and simple integration into different applications.

RollerDrive is based on the fundamental principle of decentralizing and modularizing conveyors with zero pressure accumulation. Conventional conveyor sections are powered by 400V gear motors. These motors drive long flat belts that usually run 24 hours a day, regardless of how many goods are actually being transported. In this case, the respective conveyor zone is switched on and off using pneumatic or electric control units.

A system driven by RollerDrive in principle features a decentralized design: There is no central drive station, the drives are located in each individual conveyor zone. This design allows for activating and deactivating every conveyor zone individually. The advantage: The conveyor system will move only if goods are present. In the process, only RollerDrive that are required for optimum throughput of the goods are powered. With typical throughput rates of 600 to 1800 pieces of transport material per hour, this translates into an enormous potential energy savings, as well as reduction of noise and wear. Compared with a centralized drive system, a conveyor system powered with RollerDrive allows for saving up to 50% energy on average.

A drive solution with RollerDrive is not only the perfect solution for new systems. Existing centrally driven systems can also be conveniently retrofitted. In many cases, the conveyor rollers in use can continue to be used. In every conveyor zone, only one roller has to be replaced by a RollerDrive. With the RollerDrive controls from Interroll, the interface to the existing control system infrastructure can be easily set up.

Advantages – RollerDrive make a system easier to control and therefore save energy. This is due to the decentralised drive technology: The drives are situated in every individual conveyor zone. The conveyor zones can therefore be switched on or off completely independently of each other. This enables more specific use of the system and prevents wear and tear of the complete system. Compared with centrally driven conveyors, power consumption can be reduced by 50 %.

Texam Ltd are a leading UK distributor of Interroll products such as powered rollers and motorised drums. Our sales team will offer technical support to ensure the correct product is selected. We supply and deliver Interroll products throughout the whole of the UK, Northern Ireland and Ireland.